6G Terahertz Devices Demand 3D Electronics

[ad_1]

Smartphones have a scaling problem. Specifically, the radio-frequency (RF) filters that every phone—and every wireless device in general—uses to extract information from isolated wireless signals are too big, too flat, and too numerous. And without these filters, wireless communications simply wouldn’t work at all.

“They are literally the entire backbone of wireless systems,” says Roozbeh Tabrizian, a researcher at the University of Florida in Gainesville.

So Tabrizian and other researchers at the University of Florida have now developed an alternative three-dimensional RF filter that can save space in smartphones and IoT devices. If these 3D filters one day replace bulky stacks of 2D filters, it would leave more room for other components, such as batteries. They could also make it easier to push wireless communications into terahertz frequencies, an important spectrum range being researched for 6G cellular technologies.

“Very soon, we’ll have trillions of devices connected to wireless networks, and you need new bands: You just need a whole range of frequencies and a whole range of filters.” —Roozbeh Tabrizian, University of Florida

The filters currently used by wireless devices are called planar piezoelectric resonators. Each resonator is a different thickness—a resonator’s specific thickness is directly tied to the band of wireless frequencies that the resonator responds to. Any wireless device that relies on multiple bands of spectrum—increasingly commonplace today—requires more and more of these flat resonators.

But planar resonator technology has revealed a number of weaknesses as wireless signals proliferate and as the spectrum those signals relies on broadens. One is that it’s getting more difficult to make the filters thin enough for the new swaths of spectrum that wireless researchers are interested in harnessing for next-gen communications. Another involves space. It’s proving increasingly challenging to cram all of the signal filters needed into devices.

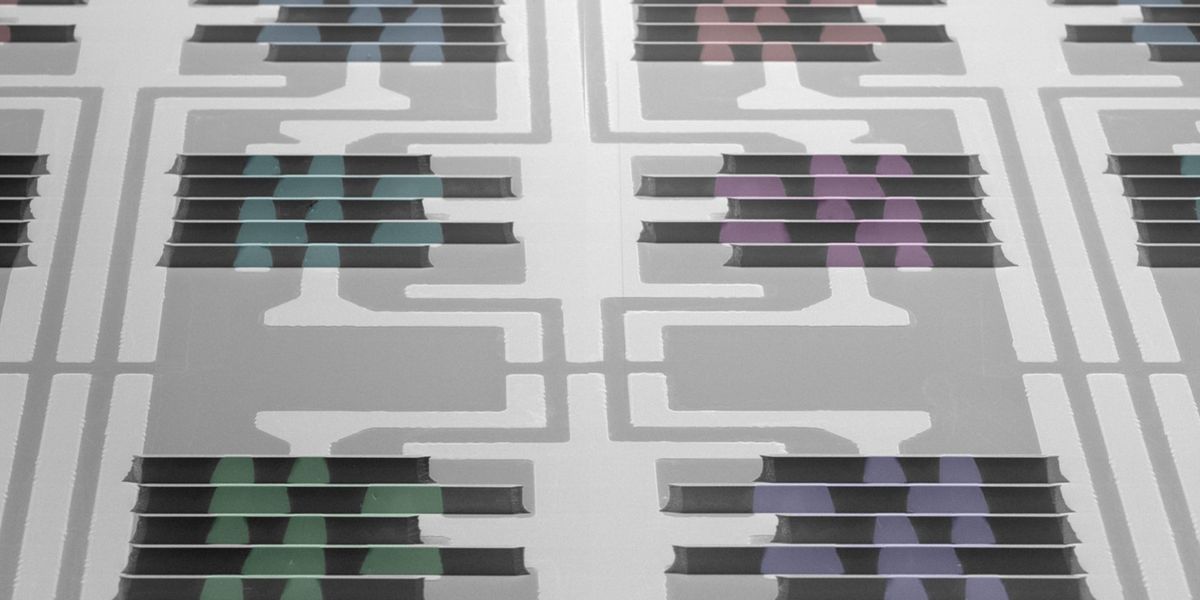

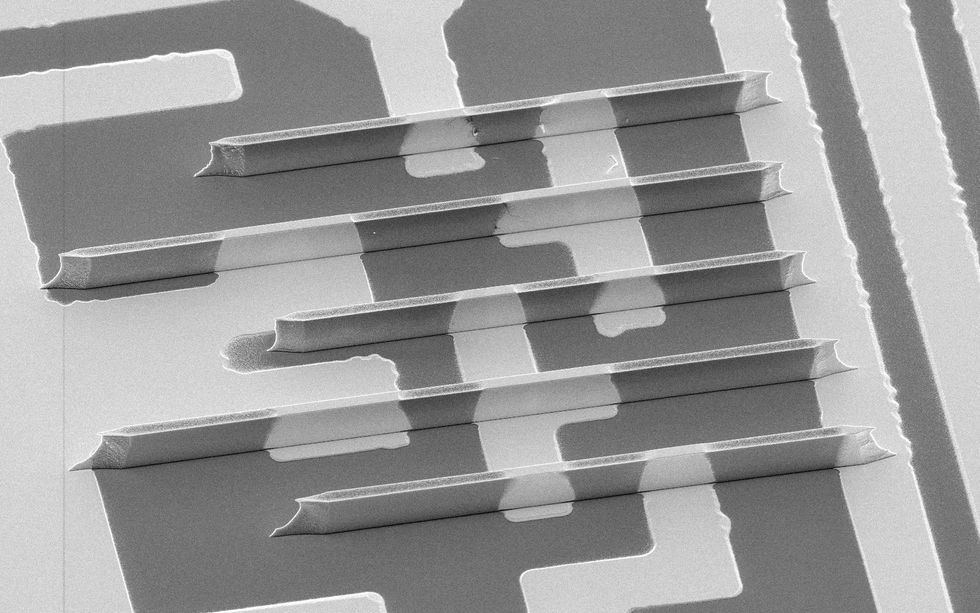

The vertical fins for ferroelectric-gate fin resonators can be constructed in the same manner as FinFET semiconductors.Faysal Hakim/Roozbeh Tabrizian/University of Florida

The vertical fins for ferroelectric-gate fin resonators can be constructed in the same manner as FinFET semiconductors.Faysal Hakim/Roozbeh Tabrizian/University of Florida

“Very soon, we’ll have trillions of devices connected to wireless networks, and you need new bands: You just need a whole range of frequencies and a whole range of filters,” says Tabrizian. “If you open up a cellphone, there are five or six specific frequencies, and that’s it. Five or six frequencies cannot handle that. It’s as if you have five or six streets, and now you want to accommodate the traffic of a city of 10 million people.”

To make the switch to a 3D filter, Tabrizian and his fellow researchers took a page from another industry that made the jump to the third dimension: semiconductors. When, in the continuous quest to shrink down chip sizes, it seemed like the industry might finally be hitting the end of the road, a new approach that raised electron channels above the semiconductor substrate breathed new life into Moore’s Law. The chip design is called FinFET (for “fin field-effect transistor,” where “fin” refers to the shark-fin-like vertical electron channel).

“The fact that we can change the width of the fin plays a huge role in making the technology much more capable.” —Roozbeh Tabrizian, University of Florida

“We definitely got inspired [by FinFETS],” says Tabrizian. “The fact that planar transistors were converted to fins was just to make sure the effective size of the transistor was smaller while having the same active area.”

Despite taking inspiration from FinFETs, Tabrizian says there are some fundamental differences in the way the vertical fins need to be implemented for RF filters, compared to chips. “If you think of FinFETs, all the fins are nearly the same width. People are not changing the dimension of the fin.”

Not so for filters, which must have fins of different widths. That way, each fin on the filter can be tuned to different frequencies, allowing one 3D filter to process multiple spectrum bands. “The fact that we can change the width of the fin plays a huge role in making the technology much more capable,” says Tabrizian.

Tabrizian’s group have already manufactured multiple three-dimensional filters, called ferroelectric-gate fin (FGF) resonators, that spanned frequencies between 3 and 28 gigahertz. They also constructed a spectral processor comprised of six integrated FGF resonators that covered frequencies between 9 and 12 GHz (By way of comparision, 5G’s coveted midband spectrum falls between 1 and 6 GHz). The researchers published their work in January in Nature Electronics.

It’s still early days for 3D filter development, and Tabrizian acknowledges that the road ahead is long. But again taking inspiration from FinFETs, he sees a clear path of development for FGF resonators. “The good news is we can already guess what a lot of these challenges are by looking at FinFET technology,” he says.

Incorporating FGF resonators into commercial devices someday will require solving several manufacturing problems, such as figuring out how to increase the density of fins on the filter and improving the electrical contacts. “Fortunately, since we already have FinFETs going through a lot of these answers, the manufacturing part is already being addressed,” Tabrizian says.

One thing the research group is already working on is the process design kit, or PDK, for FGF resonators. PDKs are commonplace in the semiconductor industry, and they function as a kind of guidebook for designers to fabricate chips based on components detailed by a chip foundry.

Tabrizian also sees a lot of potential for future manufacturing to integrate FGF resonators and semiconductors into one component, given their similarities in design and fabrication. “It’s human innovation and creativity to come up with new types of architectures, which may revolutionize the way that we think about having resonators and filters and transistors.”

From Your Site Articles

Related Articles Around the Web

[ad_2]

Source link